The API Manufacturing Process

The production of APIs is a multi-step process that encompasses synthesis, purification, and formulation stages.

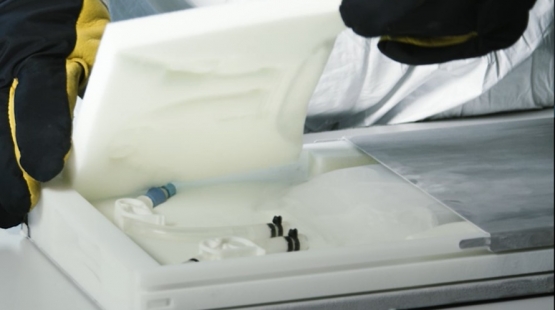

The manufacturing process begins with the synthesis of the active ingredient, where chemical reactions are carefully controlled to produce the desired compound. This synthesis step involves selecting appropriate starting materials, applying specific reaction conditions, and optimizing process parameters to achieve high yields and purity levels.

Following synthesis, the API undergoes purification processes, such as crystallization, distillation, or chromatography, to isolate and remove impurities, ensuring the final product meets stringent quality standards.

Once purified, the API is formulated into dosage forms, such as tablets, capsules, or injections, using excipients and other additives as necessary to enhance stability, solubility, and patient acceptability.

API manufacturing is subject to rigorous regulatory oversight to protect public health and ensure compliance with quality standards. Regulatory authorities, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), establish guidelines and requirements for API production like current Good Manufacturing Practices (cGMP), including documentation of manufacturing processes, validation of analytical methods, and submission of regulatory filings.13